- Home

- Products

- Anti Deformation Low Reflection Glass

- Low Reflective Laminated Glass

- Ultra White Laminated Glass

- Low Reflection Photo Frame Glass

- Explosion Proof Wired Glass

- Night Pearl Colored Background Wall Glass

- Oil sand velvet wire partition screen glass

- Artistic anti smash laminated partition glass

- Bamboo wire partition glass

- Colorful laminated glass

- Laminated embossed art glass partition

- Laminated gradient glass partition

- Marble partition glass

- Mirror Art Laminated Glass

- Wire explosion proof partition water pattern art glass

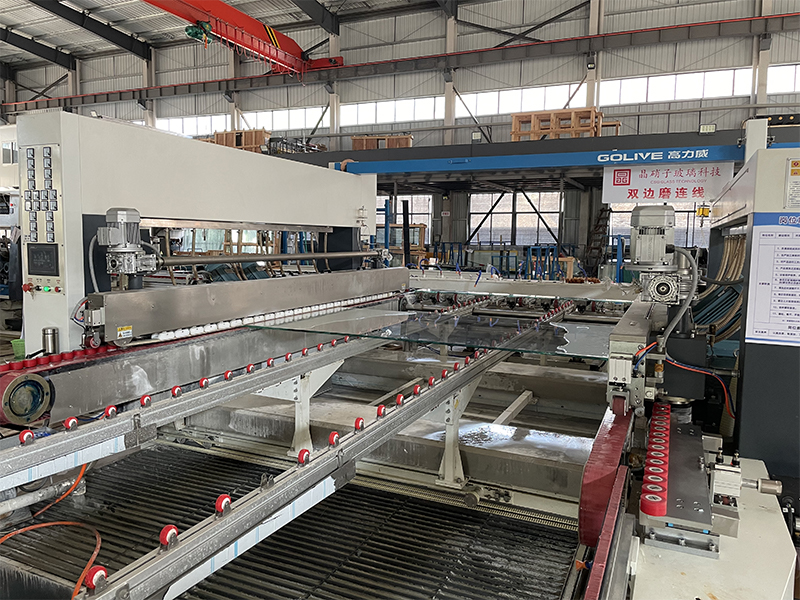

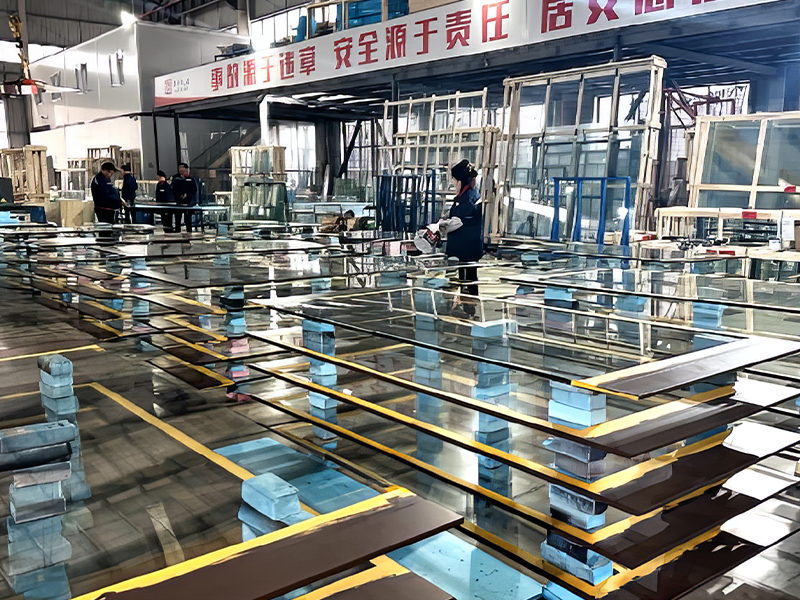

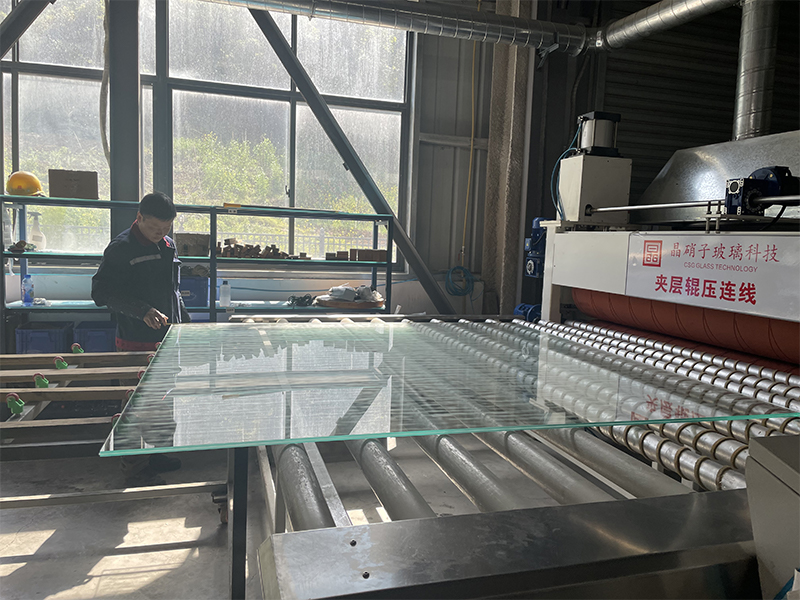

- About Us

- Why Choose CSG

- Case

- Contact