Content

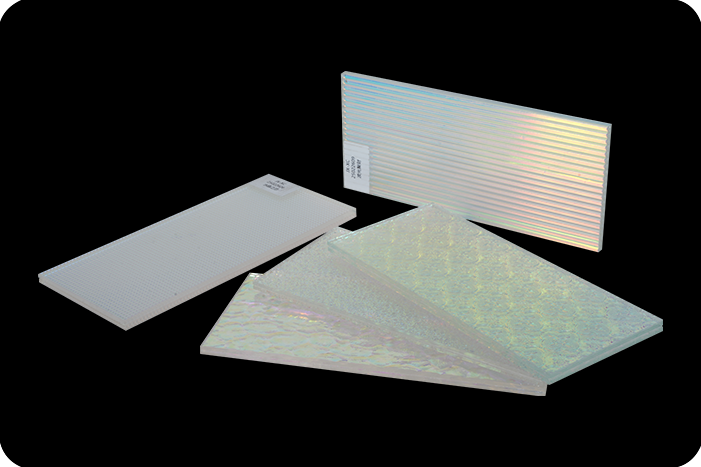

What Is Colorful Laminated Glass

Colorful laminated glass is a type of safety glass produced by bonding two or more glass panels with a colored interlayer under heat and pressure. The interlayer, commonly made from PVB, EVA, or SGP materials, not only holds the glass together if breakage occurs but also introduces controlled color and visual effects. This combination allows the glass to provide both functional safety performance and decorative value.

Unlike surface-coated or painted glass, the color in laminated glass is embedded within the interlayer. This structure helps maintain long-term color stability while supporting consistent light transmission and visual uniformity across large glass areas.

Manufacturing Structure and Color Formation

The manufacturing process of colorful laminated glass involves precise alignment of glass sheets and colored interlayers, followed by lamination in an autoclave or vacuum system. During this process, the interlayer melts and bonds tightly to the glass surfaces, creating a permanent composite structure.

Color can be achieved through solid-tone interlayers, translucent films, or patterned color layers. The final visual effect depends on interlayer thickness, pigment density, and the number of laminated layers used in the assembly.

Common Interlayer Options

- PVB interlayers for balanced optical clarity and color consistency

- EVA interlayers suitable for decorative and interior applications

- SGP interlayers for projects requiring higher structural performance

Key Performance Characteristics

Colorful laminated glass offers a combination of safety, durability, and visual control. When subjected to impact, the interlayer retains glass fragments, reducing the risk of injury and maintaining panel integrity.

In addition to safety performance, the colored interlayer can filter sunlight, reduce glare, and control visible light transmission. This makes the glass suitable for applications where both aesthetics and environmental performance are required.

- Fragment retention after breakage

- Improved sound insulation compared with monolithic glass

- Stable color performance under indoor and outdoor exposure

Design Flexibility and Color Options

One of the main advantages of colorful laminated glass is its design flexibility. Architects and designers can select from a wide range of colors, from subtle neutral tones to bold accent shades, depending on project requirements.

Color density can be adjusted to achieve transparent, translucent, or semi-opaque effects. Multiple interlayers may also be combined to create gradient or layered color appearances.

| Color Effect | Visual Characteristics | Typical Applications |

| Light tint | High transparency with soft tone | Facades and windows |

| Medium color | Balanced light and privacy | Partitions and balustrades |

| Deep color | Strong visual emphasis | Decorative walls and feature panels |

Typical Applications of Colorful Laminated Glass

Colorful laminated glass is widely used in architectural and interior projects where visual identity and safety are both important. Its layered structure supports use in areas subject to human contact or regulatory safety requirements.

Architectural and Exterior Use

In building facades, skylights, and canopies, colorful laminated glass provides visual distinction while maintaining safety performance. The interlayer helps control sunlight and enhances the exterior appearance without relying on surface coatings.

Interior and Decorative Applications

For interior partitions, stair railings, and decorative panels, colorful laminated glass adds color depth and spatial definition. The laminated structure supports use in high-traffic areas while maintaining a clean and consistent appearance.

Installation and Selection Considerations

When selecting colorful laminated glass, factors such as glass thickness, interlayer type, and color density should be evaluated together. These parameters influence both structural behavior and visual outcome.

Installation methods should account for edge protection and framing compatibility to preserve the laminated structure. Proper specification ensures that the glass performs as intended throughout its service life.

Why Colorful Laminated Glass Is Used in Modern Design

Colorful laminated glass combines safety performance with flexible design expression. By integrating color within the laminated structure, it delivers consistent appearance, long-term durability, and functional protection.

This balance of visual impact and practical performance makes colorful laminated glass a widely adopted material in contemporary architectural and interior design projects.