The reduced reflection effect of low-reflection picture frame glass is produced using the advanced magnetron sputtering coating technology in the world. In the production process, ordinary reinforced glass is put into a vacuum chamber and then bombarded with a target material by an electron beam or an ion beam to produce a high-energy plasma, which evaporates the metal, alloy, or compound target material into a gas and deposits it on the surface of the reinforced glass, forming a precision multilayered film a few nanometres to tens of nanometres thick.

These films can adjust the interference of light of different wavelengths reflecting off the surface, thus achieving a reflection reduction effect. When light hits a glass surface from the air or other media, the different refractive indices of the different media cause reflection and transmission of the light. If the glass surface coated with a reflection-reducing film is irradiated by light, the surface forms a composite reflection reflected from multiple films, and the interference of this reflection can offset part of the reflection of light, which in turn greatly reduces the reflectivity and improves the transmittance of the glass.

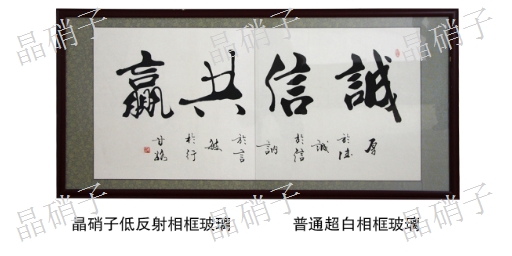

When making low-reflection picture frame glass, the film can precisely adjust the reflection and transmission of light by controlling its thickness and refractive index to achieve the effect of reducing reflection. In addition, the reflection coverage area of this multilayer film is very small, which makes the surface look smoother and reduces the interference of scattered and reflected light, thus allowing people to observe the content of the photo or artwork more directly.

In short, low-reflection photo frame glass is coated with a reflection-reducing film on the surface of the reinforced glass using magnetron sputtering coating technology, which reduces the reflection on the surface and improves the transmittance of the glass by making precise adjustments to the reflection and transmission of light. It not only protects artworks and photographs from damage but also improves the experience of viewing the artwork by more realistically reproducing the colors and details of the artwork.