Explain AR-coated reflective glass applied to the [secret] field! AR-coated reflective glass applied to different fields, coated reflective glass, is a glass material surface issue for special data processing of the glass, which compared with the development of ordinary glass has a relatively low reflection ratio. Domestic production and use of AR coated reflection-reducing glass basically can be satisfied with students some of the requirements of the transmittance level is not high for the decorative glass, architectural glass, and in the LCD display, higher picture frames, glass display cabinets and so on, the transmittance rate can not fully meet the requirements of the community. Especially in the work of optical components, reflection-reducing glass has its irreplaceable important use. Therefore, low cost, low energy consumption, low pollution, and high-quality AR-coated reflection-reducing glass main research content value exists a lot, there is a huge market demand potential.

Due to the wide recognition of the excellent performance of the reflection-reducing glass, as well as the diversification of product and application specifications and sizes, its application areas will continue to expand. Applying the existing research results to the production of reflection-reducing glass and further exploring more practical and effective manufacturing technologies for other types of reflection-reducing glass is the future development trend of reflection-reducing glass.

Main applications of AR-coated glass.

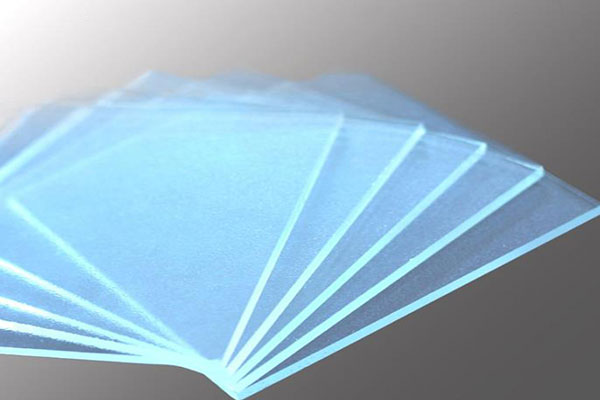

Coating the surface of ordinary tempered glass to improve the light transmittance of the tempered glass surface and achieve the function of easy cleaning. It also extends the life of the glass. At present, aluminium coated glass is mainly used in the fields of solar cell module, photo-thermal, architectural and automotive glass.

The general LCD monitor and LCD carry the TV through the front without adding the front glass. The surface is relatively easy to be scratched and damaged, and the research view angle is small. After adding also a kind of AR glass, these problems and disadvantages are to be overcome. Mainly can be used for data display control devices that protective screens such as LCD TVs, PDP TVs, laptop computers, desktop computer system displays, high-grade instrument panels, touch screens, picture frames glass, etc. to improve the transmittance to reduce the material reflectivity of electronic technology products.

AR-coated reflective glass as the main can be used as a solar thermal, photovoltaic information conversion management system of monocrystalline silicon and polycrystalline silicon solar photovoltaic cells for lighting panels, to make the electrode plate not fully learn to absorb solar energy, improve the efficiency of the photovoltaic technology conversion of the silicon battery, just need to have the ability to be as low as possible reflectance, as high as possible sunlight transmission rate. According to the principle of diffuse reflection, the surface of the fluff processing to a certain extent reduces the reflectivity of the ambient light, its low iron content of different formulations also significantly reduces our solar energy absorption rate. If we in this theoretical basis and then plated a layer of reflection reduction of the transmittance increase film, can make its development in a variety of social angle analyses of incidence conditions have a very high value of solar energy transmittance and to prevent light pollution, to achieve a relatively high solar energy resources into teaching efficiency.

After hardening on the surface of ordinary super white glass, the reduced reflection coating glass is obtained. It can effectively reduce the reflectivity of solar energy on the surface of the glass, improve the energy transmittance, and ultimately improve the power generation efficiency of solar cells. It is a new international technology and product. Photovoltaic Reduced Reverse Glass increases the visible light transmittance by 2.5%, thus improving the conversion efficiency of the AR-coated reduced reflection glass crystalline silicon photovoltaic cell module. A 1% difference in conversion efficiency means a cost difference of about 6-7%.